Pierre Rondel

07/04/2011

|

|

This

new plane manufactured by Palo & Miro Polonec (Miro

Model) . Miro Model is well known in the F1E (free fligth) world. For

example, pilots from the french national F1E team are using Miro Model planes.

This

new plane manufactured by Palo & Miro Polonec (Miro

Model) . Miro Model is well known in the F1E (free fligth) world. For

example, pilots from the french national F1E team are using Miro Model planes.

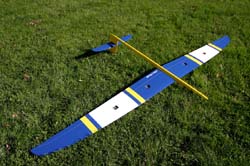

This F3F model with a wingspan of 2.95m doesn't look like other plane with its crosstail, and a very original and nice planform. The section is a DP 8.3/1.66 at the root, with an evolution to a thinner section with less camber at the tip. Another particularity is the canopy that is located at the bottom of the fuselage, servos being upside down.

Characteristics are:

Moulding quality is absolutely superb, one of the best I have seen. The finish and fitting is just perfect. To illustrate it, just assemble the 2 wings on the fuselage with the joiner to see that there is no need to force. I will not have to sand the joiner, even a little. The fit at the root is perfect.

My Ambrosia is a glass version, the fuselage is made from kevlar carbon. A 2.4Ghz friendly is available on request. The servo tray is already installed, like the control command to the tail and rudder. A small pocket with the wing servos covers and brass control horn is provided. Ballast take place in the wing on both side of the joiner, which is good to keep the balance right, while loading the plane. According to the manufacturer, the square ballast tubes accept up to 1400g of ballast (brass ballast).

Weight per element is as follow:

I can expect a flying weight around 2200 gr. As I said at the beginning, the Ambrosia F3X is manufactured by Miro Model http://miromodel.com/, located in Slovakia. You can contact them at the following address: p.polonec(at)zoznam.sk (replace the (at) by the @ to obtain a valid email address).

Ambrosia F3X assembly

First

I prepared the wing servos wire and the equivalent in the fuselage. I use DIY

plugs because you can make the exact length you need, and also because it is

much cheaper. Ambrosia F3X has MPX green plugs housing already moulded.With

a mini drill, I prepared the housing on the fuselage ad let a lip all around

in order to glue the plug in place.The plug is fixed in place with cyanoacrylate

glue. The result is perfect and clean. The Fuselage will be equiped with the

MKS DS6125-H. The servos tray is cutted for futaba S3150, I guess, but not problem

for the MKS servos. In the wing, I will use 4 DS6125 equiped with their laser

cut wood frames.The servo hole is not that big, but the frame can enter with

some exercice. Then, I continued the assembly with the servos installation,

in the fuselage and in the wings. In the fuselage, the DS6125-H are simply screwed

with the woodscrews provided. Pushrods are made from metal tube with a external

diameter of 2mm. First, I cut them at the right length before to fix a M2 treaded

coupler at the end. I used MPJet couplers made from brass because they are execellent

quality. Usually, I glued, then pinched the M2 treaded coupler on the pushrod.

Prior to that, I inserted 5cm of 1 mm pianowire in the tube in order to not

crush the tube when pinching the coupler.

First

I prepared the wing servos wire and the equivalent in the fuselage. I use DIY

plugs because you can make the exact length you need, and also because it is

much cheaper. Ambrosia F3X has MPX green plugs housing already moulded.With

a mini drill, I prepared the housing on the fuselage ad let a lip all around

in order to glue the plug in place.The plug is fixed in place with cyanoacrylate

glue. The result is perfect and clean. The Fuselage will be equiped with the

MKS DS6125-H. The servos tray is cutted for futaba S3150, I guess, but not problem

for the MKS servos. In the wing, I will use 4 DS6125 equiped with their laser

cut wood frames.The servo hole is not that big, but the frame can enter with

some exercice. Then, I continued the assembly with the servos installation,

in the fuselage and in the wings. In the fuselage, the DS6125-H are simply screwed

with the woodscrews provided. Pushrods are made from metal tube with a external

diameter of 2mm. First, I cut them at the right length before to fix a M2 treaded

coupler at the end. I used MPJet couplers made from brass because they are execellent

quality. Usually, I glued, then pinched the M2 treaded coupler on the pushrod.

Prior to that, I inserted 5cm of 1 mm pianowire in the tube in order to not

crush the tube when pinching the coupler.

Initially, I wanted to use 4 eneloop cells mounted in 2+2 format will take place easily in the nose. I finnaly changed the Eneloop by 4 Intellect 2/3A cells, 1600 mAh in order to obtain a shorter battery pack and let more place to the CG lead and the receiver. The battery has been soldered. Cells are first hot glued together. A transparent shrink tube allows a nice finish. I also prepared a small ON/OFF switch on an epoxy plate which is then screwed on the servo tray. The switch is small enough to let the space for the receiver.

On the wing side, I prepared the servo holes to receive the wood frames. Once positioned, I glued the frame with rapid expoxy (10 mn R&G epoxy), put the servo in place with a very thin plastic film in between, ajust the position of the frame & servo in order to have the servo horn well aligne with the control horn. I put a ballast on top of the servo and let everything to dry smoothly all night long. The result is clean and ready to receive the control rods which is the next step of the assembly. The Ambrosia F3X comes with the brass ring-screws. You'll need 8 clevises (M2), some threaded rod and also aluminium tube with an internal diameter of 3 mm. First of all, I grinded 4 clevises (that will be on servos side) in order to use the servos arm hole the closest to the axis.

The

servos being in place in the wings, I cutted the threaded rod at the right length,

glue with some rapid epoxy the clevis on the ailerons/flaps side. Once dry,

I glued the clevis at the other end, and inserted a 3mm aluminium tube to make

the control rod more robust and stiff. The reason I fix the clevises with rapid

epoxy glue to to suppress any possible slope on the command. You will also notice

that the ring screws are not glued in place. It will be done at the very end

because once in place, the clevises cannot be removed anymore.

The

servos being in place in the wings, I cutted the threaded rod at the right length,

glue with some rapid epoxy the clevis on the ailerons/flaps side. Once dry,

I glued the clevis at the other end, and inserted a 3mm aluminium tube to make

the control rod more robust and stiff. The reason I fix the clevises with rapid

epoxy glue to to suppress any possible slope on the command. You will also notice

that the ring screws are not glued in place. It will be done at the very end

because once in place, the clevises cannot be removed anymore.

Then, I drilled the wing plug housing at the root of the wing. The housing is at the perfect dimension for the green MPX style plug. The servos are screwed on their frame, and the command pushrod put in place. The ring screw is glued with epoxy at that time. Same for the flaps. The only difference is the servo arm neutral position with is different in order to obtain more travel down for the airbrakes: The servo covers are cut, following the moulding mark. They fit perfectly.

To finish the assembly, I just needed to install the receiver and program the servo travels and neutrals, do the balance lead to obtain the right CG, then build some ballast.

Ballasts

The

Ambrosia is not coming with the ballasts, so you have to make them. Hopefully

the dimension of the ballast compartiments is square. I found in a DIY shop

a square steel tube with the right dimension, 14x14mm, and some wood for the

spacers. I made slugs length in order to have 2 slugs per compartiment, that

is to say 4 slugs per wing. What is interesting is that compartiments are located

on each side of the joiner which garanties that the CG will not move too much

when ballasting. Each slug is about 160 g. And the total ballast weight is about

1300g, which is perfect.

The

Ambrosia is not coming with the ballasts, so you have to make them. Hopefully

the dimension of the ballast compartiments is square. I found in a DIY shop

a square steel tube with the right dimension, 14x14mm, and some wood for the

spacers. I made slugs length in order to have 2 slugs per compartiment, that

is to say 4 slugs per wing. What is interesting is that compartiments are located

on each side of the joiner which garanties that the CG will not move too much

when ballasting. Each slug is about 160 g. And the total ballast weight is about

1300g, which is perfect.

CoG

I also did the CG balance of the plane and moulded the lead for the nose. I needed around 150g of lead which is not too much considering the fin and tailplane which is usually heavier than a V-tail. The total weight is 2250g. The Ambrosia F3X is ready for maiden :) !!! I started with a CG location is at 102 mm from the leading edge, measured at the root chord.

Flight

Well,

For the very first flight, the weather conditions were totally calm air, no

wind at all with a temperature of 4° celcius. Hopefully, all the snow had melted

since the week-end before, so the slope was accessible. It was defintively not

a weather for a maiden flight, but because I was on the slope, I didn't want

to return home without launching the plane once, do a circuit and land. Surprisingly

the first flight was longer than expected and I was able to do few circuits

in absolutely dead air, with flaps, before to land, which was very encouraging.

I have been able to see the good lift provided by the section, and the good

handling of the Ambrosia, at very low speed, with no bad habits, no stall.

Well,

For the very first flight, the weather conditions were totally calm air, no

wind at all with a temperature of 4° celcius. Hopefully, all the snow had melted

since the week-end before, so the slope was accessible. It was defintively not

a weather for a maiden flight, but because I was on the slope, I didn't want

to return home without launching the plane once, do a circuit and land. Surprisingly

the first flight was longer than expected and I was able to do few circuits

in absolutely dead air, with flaps, before to land, which was very encouraging.

I have been able to see the good lift provided by the section, and the good

handling of the Ambrosia, at very low speed, with no bad habits, no stall.

Few days later, I finally had a good flying session with the Ambrosia F3X ! Despite cold temperatures, I spent the afternoon on the slope to fly the Ambrosia F3X in good wind conditions (Around 40 km/h). I flew it with 650gr of ballast over the 1300gr it can carry. If I would have to describe the Ambrosia is very few words, I would definitively say: “It tracks extremely well !“. Thanks to the fin and the full moving cross tail, the Ambrosia is a pure joy to pilot. It is fast, but especially, it is easy to fly fast, which is a very good capability from my point of view. You don’t have to fight with the plane, to correct trajectories all the time. I did hundreds of laps and turns, and I have been very impressed by its behavior in Energy Management turn style. It is so easy, remains stable, go high without slowing down. The elevator is smooth and very precise. No drag induced by a control surface, the full tail is always perfectly aligned. The Ambrosia carried the 650gr easily, and I think I could have put more ballast without problem. The DP section delivers very good performances, and speed. Acceleration are good and the energy retention also.

The next flight allowed me to focus on the reflex camber setting and the snap flaps: Adding 1 or 2 mm of reflex works well. The plane is faster in the wind, and behaves better in cross wind. For the turn with reflex, I found that it needs some snapflap to keep the grip. I have 4 mm down measured at the root, trailing edge aligned, of snap flap.

I

also fixed my problem of elevator compensation with the T12FG. I needed an offset

setting on the elevator in order to have the compensation linear and starting

as soon as I move the stick, and not starting when the stick reach the middle

of the course. What is funny is that I didn’t feel the problem on my other sailplanes,

probably because they have a V-tail. The Ambrosia F3X being crosstail and full

moving tail, it is possibly more sensitive to the compensation. Now, it is fixed,

and the landing is much comfortable with no side effect !

I

also fixed my problem of elevator compensation with the T12FG. I needed an offset

setting on the elevator in order to have the compensation linear and starting

as soon as I move the stick, and not starting when the stick reach the middle

of the course. What is funny is that I didn’t feel the problem on my other sailplanes,

probably because they have a V-tail. The Ambrosia F3X being crosstail and full

moving tail, it is possibly more sensitive to the compensation. Now, it is fixed,

and the landing is much comfortable with no side effect !

The next step has been be to confront the Ambrosia F3X against other gliders, to have some references and see how it is compared to competitors. I participated to the local winter league with the Ambrosia F3X. We managed 6 rounds at 12 pilots in very changing and challenging conditions. The slope is not very high, not sharp at all, with a fence in the middle. We saw some interesting flights where the plane was jumping the fence at each lap ! I flew my Ambrosia F3X sucessfully and won the competition against Vampires, Ascots, Ceres, and some other competitive planse. At round 5 et 6, I discovered that moving the CG bakward (by placing the ballast intentionally in the rear compartiment), the Ambrosia was more performant in the right turn with cross wind. With this new CG at 105mm, the plane had still no bad habits which indicates that I have still some margin. Overall, I'm pretty satisfied with the Ambrosia F3X. The crosstail makes it easy to pilot, and very stable. The section works very well and makes the Ambrosia a very competitive plane in addition to be a nice looking plane. Next step will be to try it on a cliff, with some vertical lift and perform some aggressive EM turns.

During the second competition with the Ambrosia F3X, and after a battle with my F3F mate Yves Tirand and his Vampire, I finally won the competition, after 10 rounds, taking the best time of the comp with 41.43s. Another point is that the Ambrosia F3X carries ballast very well. If you can climb enough during the first 30 seconds, then the plane keeps the energy very well. According to the pilots presents, the Ambrosia is pretty stable compared to other plane.

Conclusion

Conclusion

The Ambrosia is definitively a well born and well mannered plane. It is superbly well made, one of the best quality I 've seen so far. Prices are fair compared to the market (950 Euros for the glass version, and 1050 Euros fro the carbon version, both without ballast or wing bags). The Ambrosia F3X is also extremely competitive in F3F. It performed very well during the local winter league. The plane is so stable and so easy to fly. Whatever the turn style, you can place the Ambrosia and it doesn't move. This is the easiest plane I have seen and piloted. The tailplane is probably the first reason, but also the DP section.

Video

This video has been taken on a nice training slope, where I prepared the Viking Race 2010. Weather was great for beginning of February with 10° and a gentle breeze around 10 to 15 km/h. I flew the Ambrosia all the afternoon with 300gr of ballast. Here is the 4 minutes video:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Copyright ©

1998 - 2011 Planet-Soaring.com

No

commercial use or publication (e.g. on other www or ftp sites, print media)

without the written consent from the author(s)