It is not easy being a student! Especially when you have aircraft modelling as a hobby and want to make the most of both worlds.

I came from France to study in UK three years ago and got into the hobby not much later. Since then, I have acquired a few e-powered gliders and aircraft, crashed some of them…but always had a good time. One of the things you have to face when you get into the hobby is the need to go bigger.

I started with a Great

Planes Spectra 2.0m, then got an Altus XL (in fact a 1.8m Highlight), now

own a Jazz Xtreme flying wing, an Easy Street…but with my flying skills getting

better, I had to go for a 2.5 m or so.

Airtech has

a very wide range of gliders (distributed in UK by South Coast Sailplanes),

some of them able to be e-powered. One of my requirements was that it should

have an electric motor (possibly brushless), offer good aerobatics, stay up

in light lift conditions and behave well in the windy conditions we often

meet here in UK.

As an answer,

I was advised to go for their Sun, an all-round slope and field soarer that

can be very fast (or very slow) and a very efficient thermal soarer. This

is the same glider used by Airtech in F3F/F3J competition inFrance to compete

against all-moulded aircraft.

After much

thought and a lot of overtime to put the money together, I took the opportunity

of a trip back home to visit to Airtech in their workshop. My Sun was ready,

with its white fuselage and wooden wing, along with the Multiplex Micro 3BB

for the flaps and ailerons, Graupner C3341 for the elevator and rudder. The

receiver chosen was the Multiplex Micro IPD 7.

The Kit

The

first impression when you receive the kit is that this is a truly quality

product.

The

box contains:

ü A 1.6 m

centre wing panel which is already made (Obechi skinned rigid foam). Two holes

have been drilled in its centre for the wing screws. Some aluminium tubes

have been moulded for the wing tips carbon joiners

ü Two 85 cm

wing tips similarly made with tubes as well.

ü The two pieces that make the elevator (all moving and removable, made in a similar manner to the wing).

ü A built

up balsa rudder, providing the lightweight required at the tail end of the

aircraft. The rudder can be made removable for ease of transport and the fixation

system is provided.

ü The fuselage

is made of glass reinforced with Carbon/Kevlar. It comes in a choice of 5

different colours: white, red, yellow, orange and blue. A carbon canopy is

also included and already trimmed. The snake outers are already in place with

the tail plane crank and piano wires already connected.

ü All the

accessories including transparent servos covers, epoxy horns, 2x8mm carbon

wing joiners, aluminium rods and tubes, 5mm plywood…

Building

All

the gluing on the Sun is done with epoxy 5 minutes.

The wings

The

first job is to position the wing:

The

first job is to position the wing:The pins that hold the wing tips in position with respect to the centre wing panel then have to be fixed.

The tail

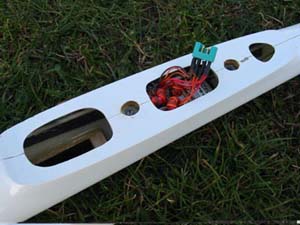

The fuselage

ü One for the receiver, which is attached to the tray with a rubber band and placed in between the two holes for the screws.

ü One for the battery with some velcro on it and, since I do not trust velcro for 100%, I secured it with a rubber band at one end so that the battery does not move in flight. The battery tray is positioned at the front of the receiver and behind the servos.

|

|

Radio installation

I installed

a Multiplex high voltage plug to connect all the wing servos to the receiver.

This allows to quickly plug 4 servos at the time into the receiver.

I did not cover my model (simply varnished it, which saves some weight as well as looks good) but this can be done easily with vinyl or heat shrink covering.

Flying

All

the throws were verified twice (and set to the manufacturer’s recommendation),

my radio programmed, I made sure everything was a tight fit in the fuselage,

the centre of gravity positioned…

All

the throws were verified twice (and set to the manufacturer’s recommendation),

my radio programmed, I made sure everything was a tight fit in the fuselage,

the centre of gravity positioned…

First impression was a good climb rate, but I did not get that rocket-like climb told by the manufacturer. Nevertheless, the handling was easy and no trim was needed (apart from the one the position the elevator).

I ran the receiver antenna outside the fuselage as an attempt to solve the interference problem, programmed some down elevator (2mm) in the butterfly mix…and the third flight was magic. With no interference, a more powerful battery (charged on-site), I finally got the rocket-like climb. After 30 seconds of motor, the Sun had sufficient altitude to make some tests. With some down-flaps, it becomes a real thermal soarer and can be slowed down a lot.

With no flap mixing, it is a very fast model and produces a magic whistle (probably due to the spinner). The basic aerobatics are good too (with some aileron to flap mixing) considering its size, but it needs a lot of altitude since it comes down very quickly. I also played with the elevator to flap mix (F3F style) and the turn are very tight but not advised from a flat field.

Conclusion

After

some thought regarding its size, the Sun turned out to be a safe upgrade to

a 1.8m glider. A good experience with building and flying with ailerons is

needed before having a Sun but I think it is very easy to handle and therefore

would make a great model for someone who is looking for an upgrade to a 2.0m

glider. A competition flyer will also enjoy the Sun because it can be very

fast and a great performer once correctly set… and at this price, one is not

scared to take it to the field on a busy and sunny day whilst moulded are

grounded.

After

some thought regarding its size, the Sun turned out to be a safe upgrade to

a 1.8m glider. A good experience with building and flying with ailerons is

needed before having a Sun but I think it is very easy to handle and therefore

would make a great model for someone who is looking for an upgrade to a 2.0m

glider. A competition flyer will also enjoy the Sun because it can be very

fast and a great performer once correctly set… and at this price, one is not

scared to take it to the field on a busy and sunny day whilst moulded are

grounded.

Name: Sun

Model type: Electric F3J glider (also

called F5J)

Manufacturer: Airtech (www.airtech-rc.com)

UK Distributor : South Coast

Sailplanes (www.south-coast-sailplanes.com)

Tel: 01202 395 707

Price: 379 euros + p&p (about

£240)

Construction: Carbon/Kevlar reinforced

Epoxy fuselage

Obechi skinned

wing

Wingspan: 3.33 m (130 “)

Length: 1.54 m (60.6 “)

Weight: 2.81 Kg (99.1 ounces)

Wing area: 65 dm2 (1007.5

sq inches)

Wing loading: 43.2 g/dm2 (0.098

oz/sq inch)

Wing section: S3021

Motor & Controller: Brushless Electronic

Model Elios 25 geared 3.7:1 with Flash 40/60 controller

Receiver: Multiplex Micro 7 IPD

Propeller: RFM 14.5 x 10” slim

Servos: 2 x Graupner C3341 +

4 x Multiplex Micro 3BB

Control functions: Rudder, Elevator, Aileron,

Flaps, Throttle

No commercial use or publication (e.g. on other www or ftp sites, print media) without a written consent.